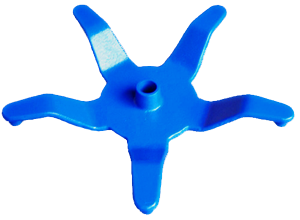

Custom Sand Casting

Control does Detailed DFM’s for casting & machining.

All finishes including paint, powder coating.

We are ISO 9001 & ISO 13485 certified.

Sand casting works for a wide variety of metals – Including High melting temperature steels, Nickel, Aluminum, Bronze, Brass, Titanium, Grey and Ductile Irons, as well.

Automated sand cast is a very fast, high production process for casting Grey Iron, and Ductile Iron. As we require Metal patterns, they tend to have a little higher initial tooling costs. But the quality and reproduction

of detail tends to be excellent.

The pattern is pressed into two halves of a sand "die". The sand halves are pressed together and the Molten metal is gravity poured into the assembly.

After cooling, the sand shell is broken away. (The sand can be recycled for reuse). Parts are then "cleaned up" (machine, or sand the parting lines, and any secondary operations). Most parts get a coating

– such as wet paint, E coat, or even powder coating.