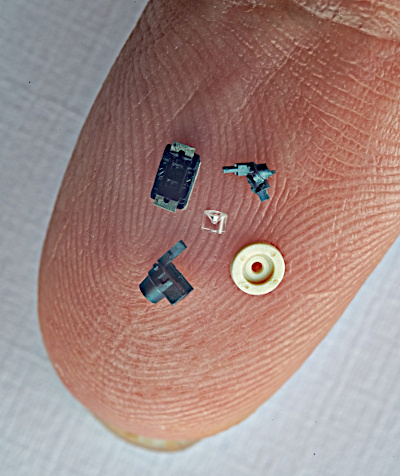

Custom Injection Molds

At Control Plastics, we know that we cannot be successful, unless your needs are met successfully.

We strive to help our customers get into production as quickly as possible.

We can help you with injection molding, die casting and more.

Control operates under ISO 9001 & ISO 13485 Standards.

We can qualify injection molds through IQ/OQ/PQ for Medical Products.

We can make your mold in the USA or in Asia; or initially in Asia to gradually transfer manufacturing to our U.S. facilities.

We will supply just molds, or molds and molded parts.

On Injection Molding

-

- Functionality: Work directly with your designers to insure excellent function for your injection molded parts. We back your designers with our CAD and CAE capabilities. All our sales engineers are experienced and capable.

- Material Selection: We consult to help optimize raw materials selection for each injected molded component.

- Process Selection: We strive to find the right injection molds and process for the most economical and capable production of your Injection Molded Parts.

- DFM/DFMA Reviews: We conduct thorough DFM Reviews. Our engineers are diligent on ALL details needed for injection tooling, and post molding processes when needed.

- Mold Flow/Moldex 3D:

We use Moldex 3D and Moldflow help to optimize Mold filling, mold cooling, part warp, as well as sink, air traps, short shots, thin and thick plastic, thin mold steel, ejection issues, gating and parting line considerations. Our goal is to solve the issues before we cut steel, and to eliminate as much of the tune up cycle as possible. - Progress Reports: We provide in-process reports during construction of injection molds.

- Inspection Reports: We include first article reports.

- Qualification: We can provide Full Qualification, including a Capability Study Analysis, IQ/OQ/PQ qualifications, and more…

- Project Lifecycle: We examine the entire lifespan of the product. We consider the finishing, (machining, decorating), the assembly (manual and automatic), the packaging (for transfer or retail), and the product’s end-of-life. Your product’s life starts with thorough planning in the process of developing its injection molding tooling.

- Our Moldmakers / Toolmakers / Tool Shops: These have the latest equipment and capabilities for serving your needs.

- Although we still do work in all industries, our largest customer sales are for the medical device, medical equipment, medical disposables, and medical contract manufacturers.

injection molds, injection molds