Custom Die Casting, Gravity Casting, Aluminum/Alloy & Zinc

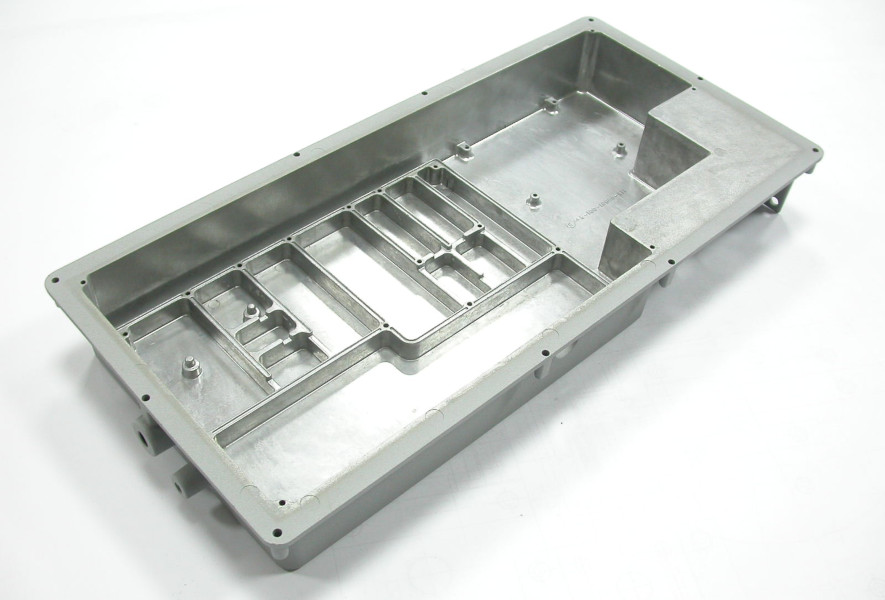

High Pressure Aluminum Die Casting (up to 2200 ton presses) and Zinc (up to 1250 ton presses).

Other Metal Casting Processes:

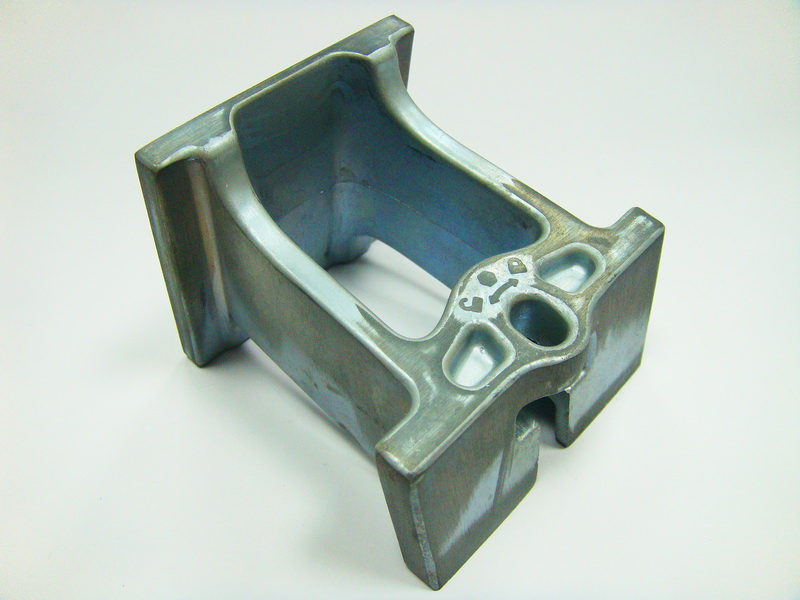

- Gravity casting of Aluminum (up to the size of 2,000mm*2,000mm*1,000mm)

- Centrifugal Casting

- Investment casting of most metals

- Sand Casting of ferrous and non ferrous metals

ISO 13485 Certified both in USA & Asian facilities

In Gravity, Aluminum and Alloy Die Casting the hot molten metals cause heat-checking, erosion, and soldering in the dies.

Die Tooling is created with a different set of constraints than is used for high pressure processes with lower temperatures – such as injection molding. We run all metal and plastic products under ISO 9001 & ISO 13485. Die Casting and Gravity Casting cavities and cores are usually made solid . Thin steel and core / ejector pins may be inserted in this process, however, these can wear out quickly. Many of the die casting detailing needs to be secondary machined, instead of molded / cast in. Regular maintenance of molds is crucial – and often includes Pre-stressing surfaces (Shot peening) to minimize the wear.

We can produce aluminum die castings and zinc die castings in all quantities.